The Tell-tale Art: Recognizing Use-wear on Stone Tools

Dr. Jenny Adams follows up her mano/metate identification blog with a discussion of use-wear analysis on ground stone tools.

One of the tools I have in my analysis toolbox is use-wear analysis. Use-wear analysis relies on both macroscopic and microscopic observations to recognize how tools were used. “Wear” is generally defined as the progressive loss of substance from surfaces as they move against each other. I’m sure you’ve noticed how stone steps in front of old building are concave from decades of people walking up and down them or how the letters on the keys of your keyboard are becoming faded or scratched from your fingers and fingernails. Those are observations of use-wear.

I first learned about wear analysis techniques developed by scientists called tribologists when I was trying to understand how to tell apart hide processing and food processing ground stone tools. This topic became important to me years ago when I was analyzing manos at the Museum of Northern Arizona in Flagstaff. I had the manos sorted out on my analysis table when a Hopi moccasin maker came by. He picked up the smaller ones and said that he used them to work hides for moccasins. I couldn’t believe what I was hearing because I thought they were all food processing tools.

So, how was I supposed to tell them apart? I looked at the stone surfaces under a microscope and decided that I needed to document the various patterns of abrasion and polish on the magnified surfaces. What I needed were stone surfaces that I knew were used to grind corn on metates and other stone surfaces that I knew were used to work hides. Experiments were in order!

First, I ground dried kernels with a mano and metate and worked a deer hide with a handstone. As I was grinding corn I noticed the smell of cooking corn and felt the warm mano surface. Friction! The next stop was the Science Library on the University of Arizona campus, where an entire section of the library is devoted to tribology–the study of friction, lubrication, and wear. Tribologists are searching for ways to minimize the damage caused by wear. It turns out that their descriptions of wear mechanisms fit nicely with the patterns of wear on stone tools. This started me on a long-term research project identifying use-wear patterns on all types of tools.

The use-wear patterns illustrated below are on two polishers and one abrader from the Hohokam site of La Villa in downtown Phoenix. These tools were used on three surface types: pottery, stone, and shell (click any image to enlarge and zoom).

Surprisingly, when magnified, pottery polishers and stone polishers have very different wear patterns. The stones selected for polishing pottery or stone are fine grained, meaning that the stone burnished the surface being polished rather than abrading it. The shiny surface on a well-used pottery polisher has numerous abrasions caused by temper and other particles in the clay. The pot surface becomes shiny as the finer particles of clay bond together under the pressure and movement of the polisher.

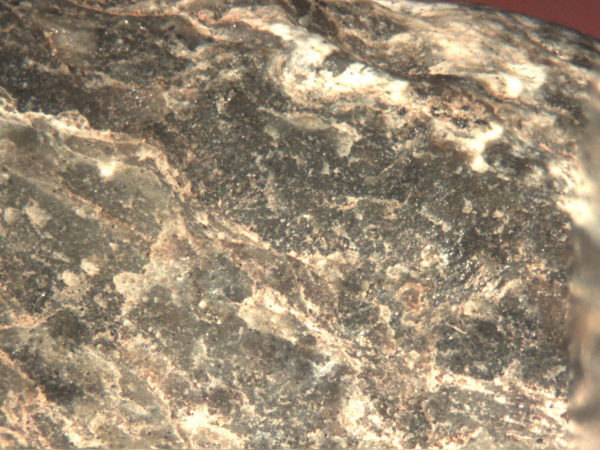

The white abrasions that look a mass of fine lines were caused by temper and particles in the clay. If looked at in the right light they can be seen on the upper edge and flat surface of the polisher. Potters like to use the ends and narrow edges of the polisher, meaning they become smoother, shinier, and darker than the flat surface.

The abrasions on the pottery polisher shown in the previous photo are easily seen when magnified 40x.

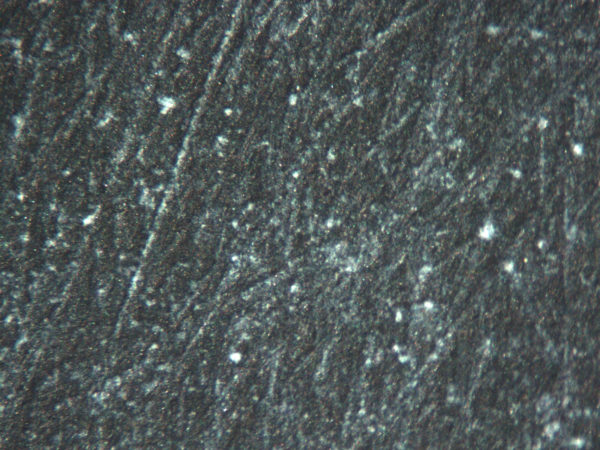

The shiny surface on a stone polisher does not have abrasions like the pottery polisher. Rather, all the high spots on the stone have been leveled, resulting in the stone polisher and the polished stone surface looking nearly identical. Pottery and stone polishers are used in the finishing stages of manufacture. The longer polishers are rubbed against the pot or stone surfaces, the brighter and denser the resultant polish (“sheen” in use-wear jargon) appears.

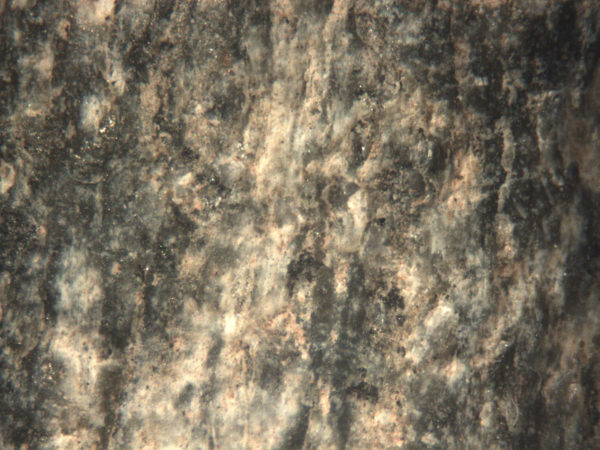

There are no abrasions visible anywhere on this stone polisher, but sheen (a shiny polished surface) can be seen on each end. Like potters, people who polish stone surfaces like to use the ends and edges of the tool more than its large flat surfaces.

This microphotograph was taken where the less used, central flat surface meets the shinier, more worn end of the tool. When magnified 40x, it is easy to see the difference—note how the grains on the left (less use) are more angular and distinct than the worn-down grains on the right (more use).

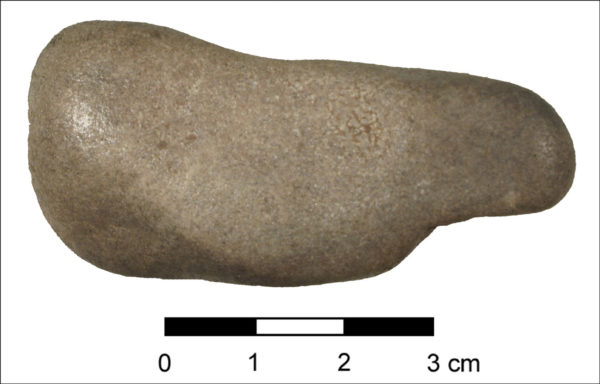

A more granular rock texture is selected for any abrader to be used in the forming stages of shell ornament manufacture. Shell is naturally softer and less abrasive than stone or pottery, and it leaves distinctive wear patterns on the abrader. The shell is hard enough to round the higher points of the stone’s microtopography (“asperities”), but not soft enough to reach into the deep cracks and crevices (“interstices”). Interestingly, on the tool pictured below, wear from the shell can be distinguished from wear caused by handling. Skin is soft enough to push into the deepest interstices and, with enough repeated use, round them as well as the asperities.

Use-wear is more difficult to see on this tool without the aid of a microscope. As seen on the polishers, the edges and ends of the abrader were preferred by the shell worker. There are no abrasions visible on this tool and no sheen.

At 20x magnification, it is also easy to see how holding the tool in the hand has darkened and rounded both the asperities and interstices of the stone. Compare the rounded and smoothed topography in this photo to the unused, unheld portion of the tool in the photo above.

Where the abrader was worked against the shell, the subtle rounding of the asperities (white ovals) is easiest to see at 40x magnification. Note that there is no rounding in the interstices (black oval).

Use-wear studies on ground stone tools are much newer to archaeologists than use-wear studies on flaked stone tools. Here are a few references to check out for more examples of how use-wear analysis is being incorporated into ground stone studies.

Adams, Jenny L.

1988 Use-Wear Analyses on Manos and Hide Processing Stones. Journal of Field Archaeology 15:307-315.

2014 Ground stone use-wear analysis: a review of terminology and experimental methods. Journal of Archaeological Science, 48:129-138.

Dubreuil, Laure

2004 Long-Term Trends in Natufian Subsistence: A Use-Wear Analysis of Ground Stone Tools. Journal of Archaeological Science 31(11): 1613-1629.

Hamon, Caroline

2008 Functional Analysis of Stone Grinding and Polishing Tools from the Earliest Neolithic of North-Western Europe. Journal of Archaeological Science 35:1502-1520.

Delgado-Raack, Selina, David Gomez-Gras, and Roberto Risch

2009 The Mechanical Properties of Marcrolithic Artifacts: A Methodological Background for Functional Analysis. Journal of Archaeological Science 36:1823-1831.